PVC glazed tile production line

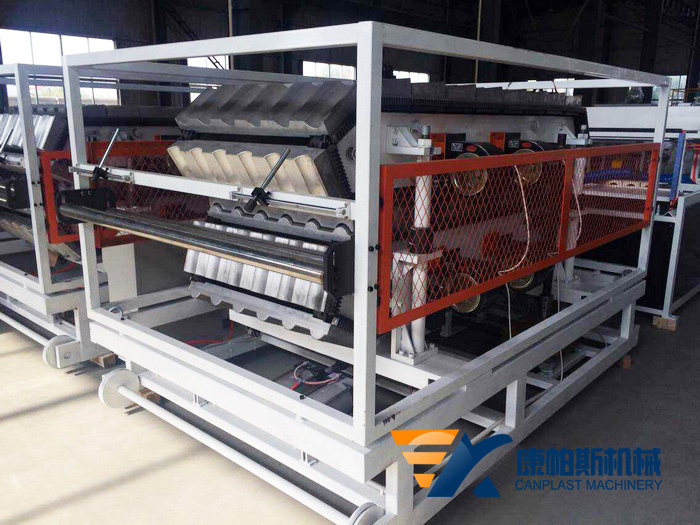

PVC glazed tile production line is composed of two conical double screw extruders, one single screw extruder, co-extruding distributor, extrusion mold and forming auxiliary equipment, glazed tile production line adopts three layer co-extrusion technology which is pioneered by plastics machinery industry, glazed tile adopts two layer co-extrusion technology, completed processing in one step, each layer materials have the function of surface materials: with super weatherability resin, ensure product durability and chemical resistance; the underlying material: white ductile material, to increase the sense of space and the brightness of work plant. Two different materials gave respective characteristics of their products, smooth surface and the organic combines together, PVC glazed tile production line is able to continuous produce PVC single layer or PVC/PMMA and PVC/ASA co-extruded tile. PVC glazed tile production line has the advantages of high production efficiency, simple operation, reasonable structure, convenient maintenance, long life characteristics.

Features of Glazed tile:

Super weathering resistance, long service life

Synthetic resin tile (composite glazed tile) using ASA high weatherability resin as the surface material. This high weatherability resin is suitable for outdoor application. It has exceptional durability in the natural environment, it can keep the stability of color and physical properties even exposed to ultraviolet light, moisture, heat, cold and shock for long time. Long service life avoids two construction waste and pollution.

Excellent corrosion resistance

Natural Anti corrosion performance, the high weatherability resin on surface and the main PVC resin of synthetic resin tile (composite glazed tile) has good corrosion resistance, which is the colored steel tile and metal tiles do not possess, its performance will not be decreased by rain or snow erosion, therefore it can resist corrosive acid, alkali, salt and other chemicals for long time, which is very suitable for application in coastal areas with strong salt fog corrosion performance and areas with serious air pollution.

Excellent anti load performance

Synthetic resin tile (composite glazed tile) has good anti load performance, in the support interval of 660mm, loading 150kg, tile has no cracks, no destruction.

Good impact resistance and anti low temperature effect

The tile has no crack when 1 kg heavy steel hammer drops from 1.5 meters high, after 10 freeze-melt cycles (-20+50 degrees Celsius), product has no bubble, blistering, peeling or cracking phenomenon.

Thermal insulation & energy saving

Whether cold or hot, synthetic resin tile reduces the impact of outside bad climate on roof, two-way balance temperature, warm in winter and cool in summer, saving energy.

Long-lasting color

The surface adopts super high weatherability engineering resin, not only can ensure the surface color gorgeous and lasting, but also guarantee not fading for 20 years, if need to change color with the new plan, without replacement, only re-painting.

Self-cleaning effect

Synthetic resin tile (composite glazed tile) has dense & smooth surface, not easy to absorb dust, with "lotus effect". It shows as new after raining washed cleanly, it won't show dappled phenomenon after raining washed

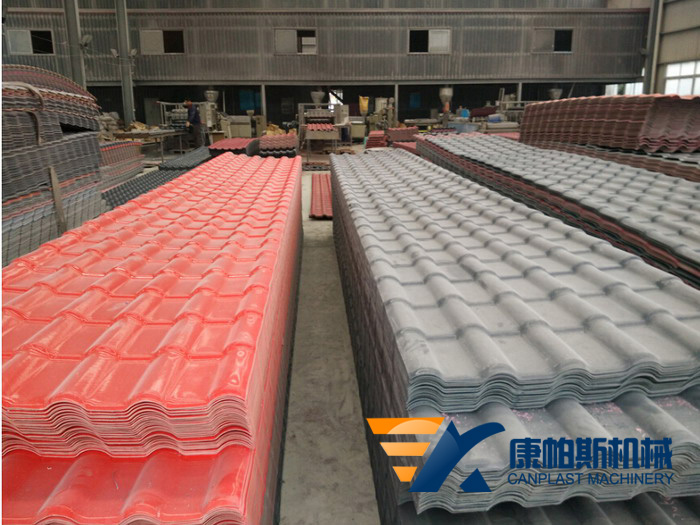

Light weight, convenient installation and safety

glazed tile weighs about 6 kg per square meter.

Synthetic resin tile (composite glazed tile) has large leaflet area, which has high efficiency of pavement.

Light weight, easy to lift, uneven surface anti-skid, safety construction

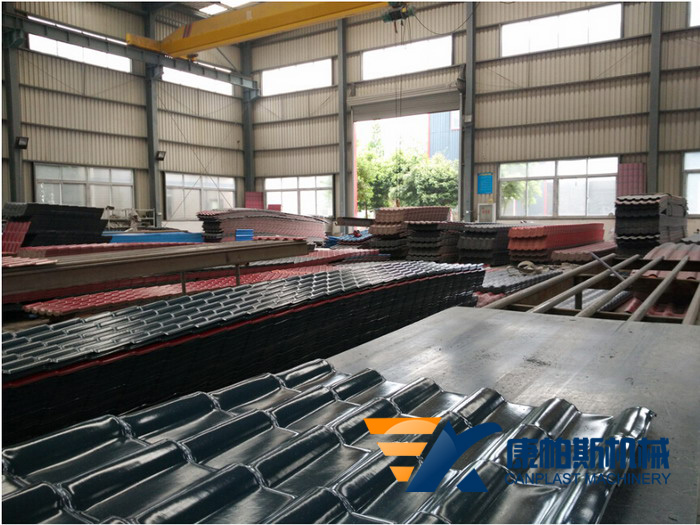

complete product range

simple tooling procedure

Green environmental-protection

Synthetic resin tile (composite glazed tile) is green environmental protection, it has no emissions, no sulfur dioxide, carbon dioxide emissions during the production and use process, it also can be completely recycled when the product used out.

Wear & scratch resistant

Synthetic resin tile(composite glazed tile) surface using pitted embossing processing, erose design on surface makes the product wear resistance, scratch resistance, even if caused small scratches accidentally during transport and handling, just gently rub.

The most prominent features of synthetic resin tile is outstanding weathering resistance, even in long-term sun exposure, under temperature variation of wind and rain and other external conditions, it won't appear fading, discoloration, cracking, strength decline or other aging phenomenon.

High fire resistance

Testing by the National Chemical Testing Center, reached the level of fire protection ability, it won’t burn or support burn, in case of fire or under high temperature to fire, not easy to spread soon, and when the fire source is removed, it stops burning immediately.

Excellent heat insulation performance

Low thermal conductivity of synthetic resin tile, so heat insulation performance has obvious advantages than other tiles.

Plastic glazed tiles are widely used in the garden type factory, scenic area pavilions, hotel villa, the exhibition hall, resorts, family and other buildings; it is the ideal production equipment for plastic product manufacturers

Qingdao Canplast Machinery welcome friends around the world to inquire with PVC glazed tile production line.

Service for PVC glazed tile production line Pre-Pre-sale: customers can consult to our company for various technique and business, our company will provide related information to facilitate reference, and provides the corresponding marketing information, sales price, sales method, to help customers know the entire market.

In-sIn Insale: after the two sides signed the contract, our company will provide corresponding design of water, electricity, air, ground installation diagram, according to customer requirements and the actual situation. After the production completed, we should inform customer in advance in order to inspect machine testing, and provide various convenience like airport pick-up, catering, hotel booking etc.

PVC glazed tile production line After-sales: after equipment completed in our company and debugging qualified, equipment arrived customer’s factory, our technician should arrive customer’s factory in time at customer’s requirements to do installation, commissioning, personnel training, technology transfer, until the user can operate independently, and produce qualified products.

Formulation and technical support: all production equipment of our company are free of charge to provide the production formula and debug the equipment according to the formula. Any problem in the production process can call us for consultation.

PVC glazed tile production line Maintenance and warranty for equipment: all equipment of our company are provided with corresponding accessories, the warranty period of our equipment is one year, operation manual and maintenance manual are offered.

Main technical parameter

|

Extruder model |

SJSZ65/132 SJSZ51/105 SJ50/30 |

SJSZ80/156 SJSZ51/105 SJ50/30 |

SJSZ80/156 SJ50/30 |

|

Raw material |

PVC+ASA |

PVC+ASA |

PVC+ASA |

|

Product width (mm) |

880 |

880-1040 |

880-1040 |

|

Product thickness (mm) |

0.5-3 |

0.5-3 |

0.5-3 |

|

Screw L/D ratio |

22:1 |

22:1 |

22:1 |

|

30:1 |

30:1 |

30:1 |

|

|

Motor power (kw) |

37 |

75 |

75 |

|

22 |

22 |

22 |

|

|

Max. extrusion capacity(kg/h) |

240 |

400 |

350 |

Our main products are:PP-PC hollow grid board production line, PE, PP, PS, PVC Board Production Line, WPC furniture-cabinet board production line,PP-PE-PVC Wood Plastic Composite Profile Extrusion Line, PP-R Cold-Hot Water Supply Extrusion Line, PVC Pipe Extrusion Line, PE-PP Gas/Water Supply Pipe Extrusion Line.

Accessory products:

Contact: mina

Phone: 13668861858

Tel: 13668861858

Email: kangpas@163.com

Add: Pingcheng East Road,Jiaozhou,Qingdao